Organic Solvent Nanofiltration (OSN)

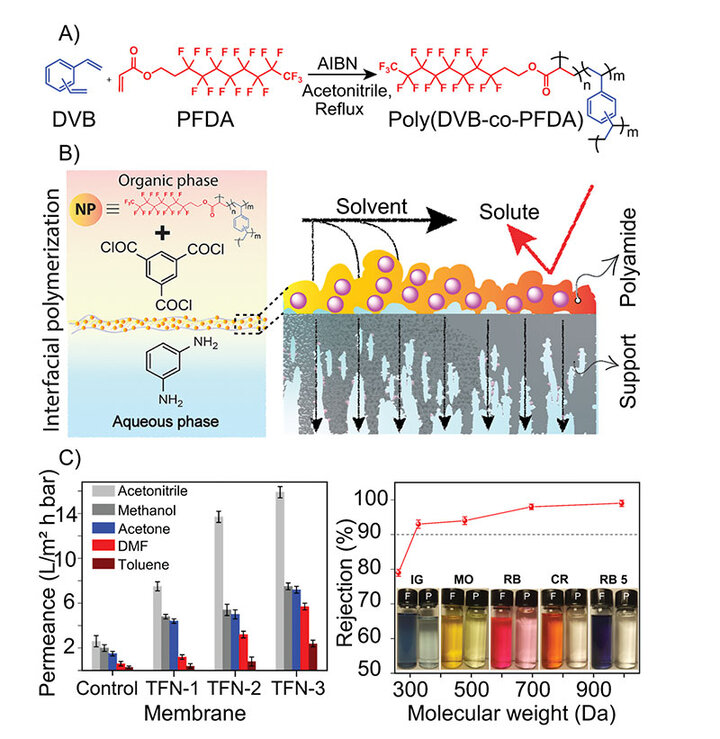

Organic solvents play pivotal roles in the chemical, semiconductor manufacturing, and pharmaceutical industries. Across many processes, significant portions of the capital and operating costs are associated with the separation processes that deal with solvents. Because conventional separation processes such as evaporation, distillation, and extraction are highly energy-intensive, membrane-based separations are now becoming more attractive. Along these lines, the use of nanofiltration (NF) membranes for organic solvent separation has found a special place, and the field of “organic solvent nanofiltration” (OSN) has been evolving very rapidly. Among different types of membranes used for OSN, thin-film composite (TFC) and their derivative thin-film nanocomposite (TFN) membranes prepared via interfacial polymerization (IP) offer superior separation performance.

Supported Ionic Liquid Membranes

This project will serve as a fundamental investigation into the optimization of Supported Ionic Liquid Membranes (SILMs) and their use for capturing and sequestering Carbon Dioxide. SILMs are primarily comprised of a solvent, a polymer, and an ionic liquid, which is an ionic salt with a melting point below 100C. These often large and bulky salts feature a variety of characteristics that are desirable for Carbon Capture, including a high thermal stability, a low vapor pressure, and a negligible volatility. Ionic Liquids have only recently entered the sphere of application, so much optimization remains to find a sustainable alternative to the ecologically harmful carbon capture systems currently in place across the globe. Current efforts are being put towards investigating the ramifications of changing the polydispersity index of the polymer used in the solutions. This project hopes to push the limits of carbon capture and help develop a more sustainable industry.

Textile Supercapacitors (TSCs)

Textile-based supercapacitors (TSCs) made by knitting yarn coated with conductive material into electrical circuits have many applications in the medicine, military, and consumer sectors. These devices are meant to collect and store energy from waste body heat and movement for delivery to personal electronic devices as a greener and more renewable alternative to Lithium-ion batteries that are currently used as a mobile power source. At PSE Bavarian Labs, we are the first group to successfully use wool as an electrode substrate in TSC research.

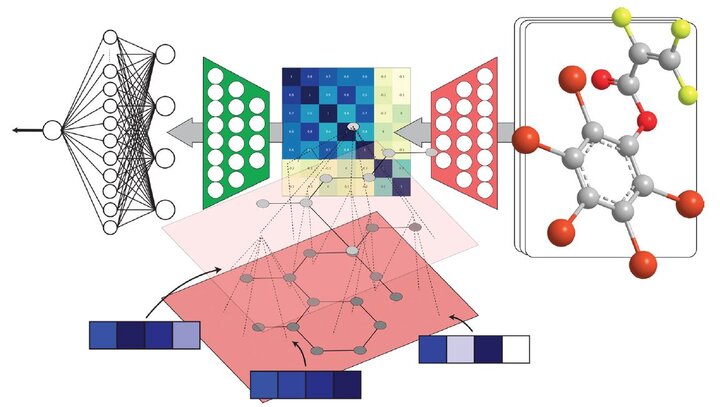

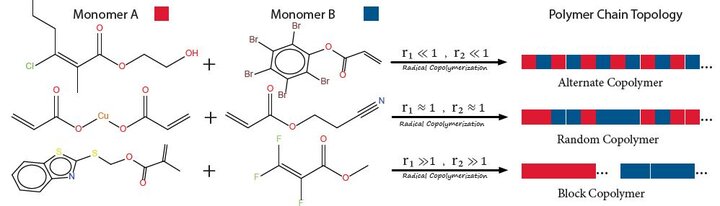

Machine Learning Framework in Polymer Science and Reaction Engineering

This project is centered on predicting polymer topology using machine learning techniques in polymer science. By leveraging advanced machine learning algorithms, the goal is to accurately predict the structural arrangement of polymer chains, which is crucial for understanding and optimizing their properties and performance. The approach involves training models on extensive datasets of polymer structures and their corresponding properties, enabling the prediction of topology for new polymer formulations. This research aims to enhance the efficiency of polymer design, facilitating the development of materials with tailored characteristics for specific applications.

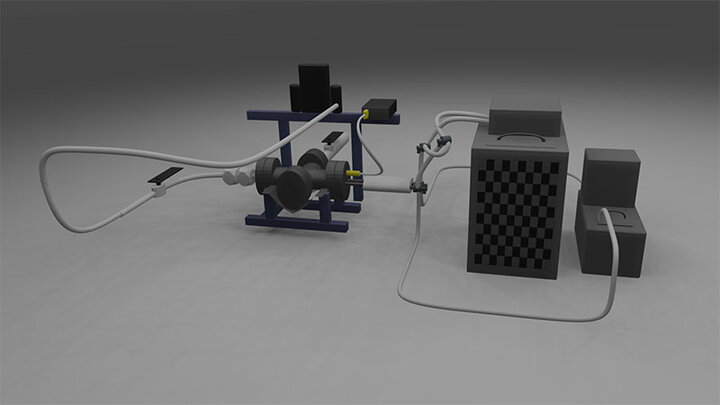

Synthesis of Copolymers Using Flow Chemistry

This project is focused on the synthesis of copolymers using flow chemistry, specifically employing a plug flow reactor (PFR). By optimizing reaction conditions within the PFR, the goal is to improve the efficiency and control of copolymer synthesis. This method allows for precise manipulation of reaction parameters, resulting in better consistency and quality of the copolymers produced. The use of flow chemistry in this context enhances scalability and reproducibility, making it a valuable approach for industrial applications and advanced polymer research.

Summer Research Experience for Teachers (RET) Program

PSE Bavarian Labs participates in the summer Research Experience for Teachers (RET) program with the Nebraska Nanoscale Facility (NNF). This is a funded position for college community educators and high school teachers to participate in summer research activities in our lab. Participants can then turn their summer work into modules to teach their students during the academic year.

When: Mid-June until the end of July.

Applications are due in April.