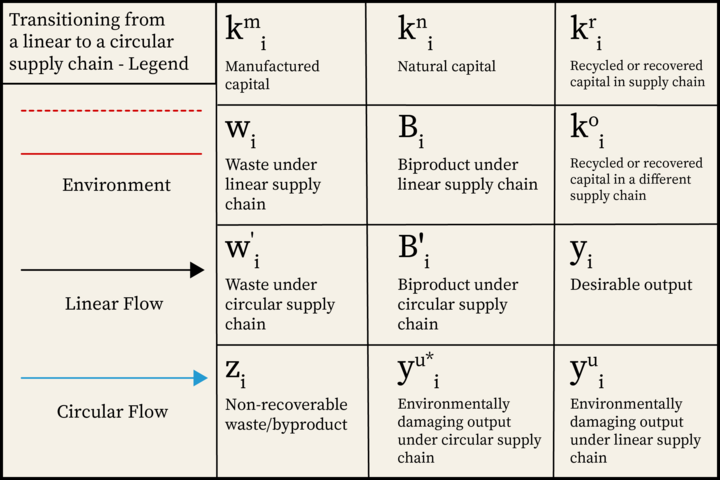

Transitioning from a linear to a circular supply chain involves several interventions throughout the chain that aim to close loops by reinvesting waste and byproducts back into itself and other supply chains.

The graphs on this page represent a general supply chain in both a linear and circular form and will walk through the various movements of resources.

This framework is general and can be adapted to capture the idiosyncrasies of a wide range of supply chains.

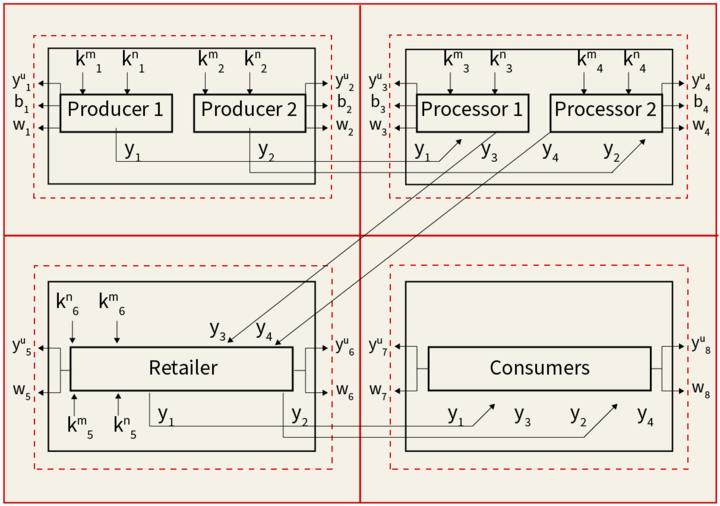

A Linear Supply Chain

A linear supply chain (LSC) has 4 distinct stages: Producers, processors, retailers, and consumers. A typical supply chain follows a linear flow from producers to consumers and each stage requires specific inputs and produces distinct outputs.

The following example provides a simple linear supply chain. The four stages are represented as quadrants.

Producer stage

For an agri-food supply chain, for example, Producer 1 could refer to crop producers while Producer 2 could be livestock production units. Natural capital could refer to inputs like land, water, and organic fertilizer - as natural capital represents natural resources used in the creation of secondary products. Manufactured capital, referring to production inputs that are not naturally occurring but instead manufactured, could refer to transportation and machinery. Environmentally damaging outputs can refer to greenhouse gas emissions, and acidification of water due to nutrient loss. Waste could be animal waste and crop residues.

Producers 1 and 2 use natural (kn1&2 ) and manufactured capital (km1&2) to produce outputs y1 and y2. This stage also entails the generation of environmentally dangerous outputs (yu1&2), byproducts (b1&2), and wastes (w1&2).

In line with our example, producers 1 and 2 utilize land, water, and fertilizer alongside tractors and other farming equipment to generate crops and livestock products. But these producers also create, among other potential harms, greenhouse gasses, animal waste, and crop residue.

Under a linear supply chain, these wastes and byproducts are discarded in the environment. While this is not always the case, the paper focuses on supply chains that discard waste and byproducts.

Processing stage

At the processing stage, processors 1 and 2 utilize natural capital (kn3&4), manufactured capital (km3&4), and stage one outputs y1 and y2 to create new outputs (y3&4). Environmentally damaging outputs (yu3&4), byproducts (b3&4) and wastes (w3&4) are also generated and discarded at this stage of the process.

Continuing with the agri-foods example, the processors at this stage could use groundwater and clean air as natural capital alongside, for example, packaging materials or slaughterhouses as manufactured capital to transform the livestock products and crops into packaged meats and animal feed. In the process, these processes create environmentally damaging outputs such as greenhouse gasses and wastewater. There is also waste in the potential form of packaging waste and inedible animal parts.

Retail stage

In this stage, y3&4 move to the retailers and are used alongside (kn5&6) and (km5&6) to create final consumer products y5 and y6. Wastes (w5&6) are discarded into the environment, alongside environmentally damaging outputs (yu5&6) at this point.

For an agri-foods supply chain, this could be represented by natural capital of air and water for ventilation and cleaning, alongside manufactured capital which could include refrigeration, buildings, or IT systems as inputs to generate the desirable outputs of produce and food. At this stage, there are no byproducts because there are no advanced production processes. Retailers sell the products to consumers, which can ultimately generate environmentally damaging outputs in the form of pollution or materials such as microplastics that remain from shipping. The waste could be in the form of unsold or expired goods.

Consumer stage

Finally, the consumption of final products (y5&6) generates waste (w7&8). These are discarded into the environment, along with environmentally damaging outputs (yu7&8).

At the final leg of the hypothetical supply chain, a potential classification of these variables could be where consumers purchase retail goods and generate environmentally damaging outputs in the form of emissions to get to and from the retail building and pollution from energy use in cooking or preparing the food products. Waste could be generated from discarded packaging as well as wholesale food waste.

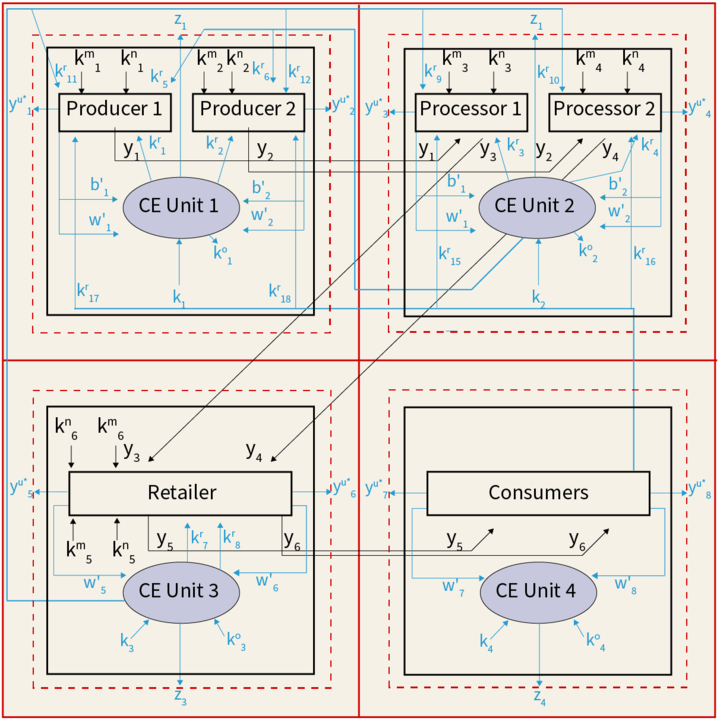

A Circular Supply Chain

The transition to a CE is characterized by closing the loops of materials and extending the lifecycle utility of wastes and byproducts to maximize value while minimizing environmental impacts.

In Figure 1, a CE unit is introduced at each stage of the supply chain.

Wastes and byproducts generally discarded under the LSC are collected and recovered by the CE units and reused as inputs in this and other supply chains.

Production stage

In the production stage, the CE unit utilizes input k1, or capital associated with the costs of implementing circularity such as collection and treatment of wastes and byproducts. Along with k1, CE unit 1 recovers and reuses wastes (w1&2) and byproducts (b1&2) to produce recycled capital (kr1&2) to be utilized by the producers, and other capital (ko1), which can be used in different supply chains.

Due to this, environmentally damaging outputs (yu1&2) are reduced and represented as yu*1&2. Finally, z1 represents the waste and byproducts that are unable to be recycled back into the supply chain.

Processing stage

In the processing stage, k2 is used in conjunction with waste and byproducts from this stage (b3&4 and w3&4) to produce recycled capital (kr3-6) and other capital (ko2). kr3&4 are reinvested into the processors and kr5&6 are returned to the previous stage to be used as inputs by the producers. ko2 can be used as an input in a different supply chain.

As with the last step, the environmentally damaging outputs (yu3&4) are reduced and represented as yu*3&4. Finally, z2 represents the waste and byproducts at this stage that are unable to be recycled back into the supply chain.

Retail stage

In the retail stage, k3 is used to recover waste (w5&6) to produce recycled capital (kr7-12), and other capital (ko3). kr7&8 are reinvested into the retailers. kr9&10 leave the retailer stage and return to the processor stage as inputs. kr11&12 are returned to the first stage to be used as inputs by the producers. Other capital at this stage (ko3) can be used as an input in a different supply chain.

As with the other stages, environmentally damaging outputs (yu5&6) are reduced and represented as yu*5&6. Finally, z3 represents the waste and byproducts that are unable to be recycled back into the supply chain.

Consumer stage

In the consumer stage, CE unit 4 recovers and reuses wastes (w7&8) as inputs with k4 to produce recycled capital (kr13-18) and other capital (ko4). Recycled capital kr13&14 are used by consumers, kr15&16 are used by the processors in the processing stage, and kr17&18 are used by the producers in the production stage. z4 represents waste and byproducts that are discarded back into the environment.

Similar to CE units 3 and 2, CE 4 increases circularity in both the same step as well as other steps in the supply chain. Finally, yu7&8 are reduced to yu*7&8 respectively due to circularity.

Through promoting circularity, the model demonstrates how resources can be reinvested into supply chains to reduce waste and byproducts - and by extension environmentally damaging outputs. While the initial fixed cost and recurring maintenance costs of these CE units can be daunting, businesses and industries that can afford the transition can see long-term reductions in costs as there is a reduced material cost for production.

Notes on the framework:

This framework is, as noted above, general. It can capture circularity at each stage of a supply chain as well as the circularity of the whole system.

It can also be applied to a variety of scales. For instance, producer 1 can refer to an individual producer or an aggregate production of a product. Similarly, processor 1 can be a specific processor or all processors of a specific product within a supply chain.

Properly adjusted frameworks for each supply chain of a region/economy could provide a region/economy-wide model of circularity which is important when evaluating aggregate circularity in a region or economy.

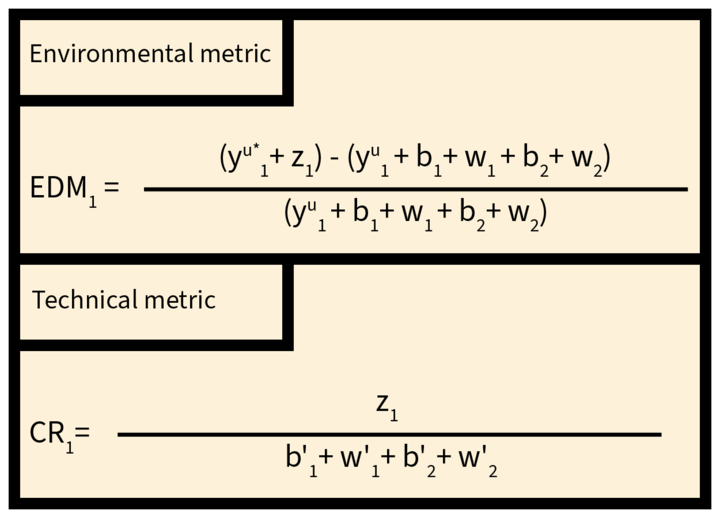

The model can also be used to provide metrics or indicators of circularity in the economic system under study. This allows measures of progress toward circularity at each stage of the supply chain, as well as at the supply chain as a whole.

In addition, the model can be used to construct environmental, technical, and economic metrics - which is especially useful as economic metrics are relatively rare in the literature surrounding circular economies.

In terms of environmental or technical metrics, the former is modeled by the reduction and mitigation of environmental damages associated with the various stages of the supply chain when transitioning to a circular supply chain. The latter is focused primarily on the circularity associated with the physical flow of inputs and outputs. They are represented below, respectively.