Building for the Moon and Beyond

Each year, NASA invites college students from across the country to compete in the Lunabotics Challenge at Kennedy Space Center in Florida. The goal? Design and build a rover that can navigate a simulated lunar terrain and collect surface material using NASA’s systems engineering principles. This competition is part of NASA’s larger Artemis mission to return to the Moon and prepare for future exploration of Mars.

How Does the Competition Work?

At the competition, teams deploy their rover into a simulated lunar zone. Their objective is to both gather and deposit as much material as possible.

The competition arena is divided into four zones:

- Starting Zone – where the rover begins its run.

- Obstacle Zone – filled with craters and large rocks that simulate lunar landscapes.

- Excavation Zone – where the rover collects lunar simulant, a crushed basalt known as BP-1 that mimics the Moon’s surface.

- Construction Zone – where the collected material is deposited.

Teams have two 30-minute runs to collect as much material as possible, following strict size, weight, and material requirements. Some teams program their rover to operate fully or partially on its own, using sensors and advanced software.

Points and awards are given to teams based on excavation, autonomy, material and power efficiency, dust control, and innovation. Additionally, teams submit several deliverables throughout the year to NASA ensuring continuing forward progression on the project.

How Does the Team Make it Happen?

NASA scores teams on technical performance, including but not limited to how well the rover excavates, conserves power, controls dust, and operates autonomously.

- Mechanical Subteams (Drivetrain, Excavation, and Hopper): These teams design and build the core systems that enable the rover to move, dig, and transport materials.

- Electrical and Programming Subteams: These groups bring the rover to life by developing the circuits, sensors and code needed to control the rover.

But, it’s not just about the rover. Teams are also judged on their communication and their impact on the local community.

- Outreach Subteam: This group leads community engagement by organizing events with local schools and campus organizations to teach others about engineering, teamwork and space exploration- one of NASA’s core missions.

- Systems Engineering Subteam: This group focuses on project documentation and systems engineering by tracking project progress, setting technical requirements and ensuring that our workflow is aligned with NASA and industry best practices.

Team leads prepare a presentation and demonstration for NASA and submit a formal systems engineering report that details the team’s process and how they followed NASA’s standards. Together, these teams follow the NASA systems engineering process from brainstorming to drawings, to final testing, turning ideas into a working robot.

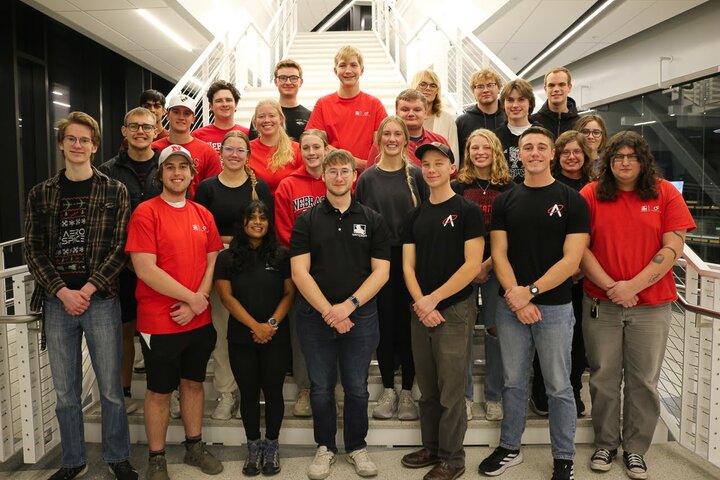

Who Can Join?

Our team consists of students who share a passion for engineering, innovation and aerospace robotics, but don’t let a lack of experience or engineering background be a barrier to joining. Whether you're studying mechanical engineering, computer science, marketing or art, there's a place for you here.

Throughout the year, members get hands-on experience beyond the classroom. You'll have the chance to contribute to every stage of the project, from researching new technologies, brainstorming solutions, designing and 3D modeling parts, writing code or even manufacturing the rover.

In Lunabotics, we do more than build more than rovers, we open doors. Team members can connect directly with NASA engineers and industry leaders, to gain valuable insight on future careers in aerospace, robotics and more.

Whether you're looking to build something incredible, make meaningful connections, or just try something new, you’re invited to be part of the journey.

2025-26 Team Leads

Team Lead: Jacob Zitek

Team Lead Apprentice: Michael Hayward

Drive Train Lead: Morgan LeMunyan

Hopper Lead: Zach McWilliams

Electrical Lead: Priyankka Nanrudaiyan

Programming Lead: Ella Moody

Excavation Lead: Samuel Schuster

Systems Engineering Lead: Karson Swartzbaugh

Outreach Lead: Alex Johnson

2024–25 Competition

The objective of the 2024–25 NASA Lunabotics Challenge was simple in theory: mine and deposit as much lunar simulant as possible, with points being weighted based on the rover’s mass and energy usage, pushing us to design a lighter and more energy-efficient machine.

Design Highlights

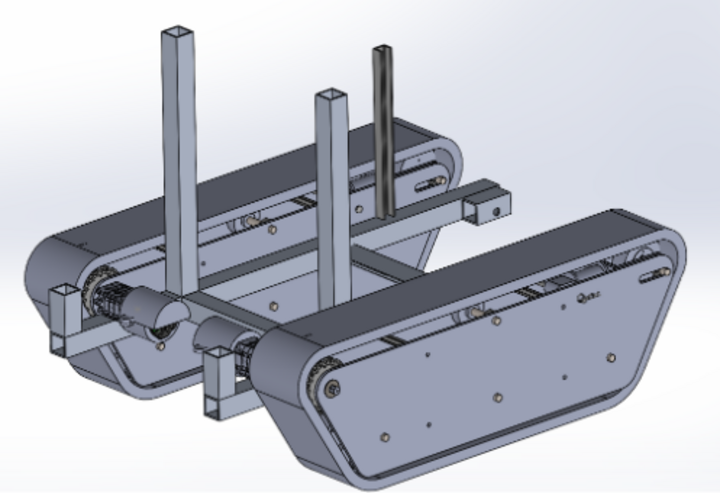

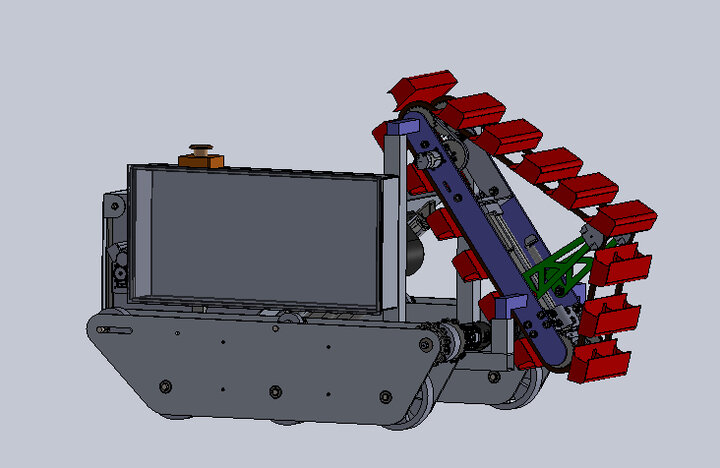

The final rover design, shown in the model below, featured several major subsystem upgrades:

- Drivetrain: The drivetrain team implemented a high-track system that keeps motors elevated for better clearance and maneuverability on rugged terrain. The tracks also provided smooth and efficient movement across the simulated lunar surface.

- Excavation: The excavation subteam developed a trencher-style digger that reaches directly into the simulant in front of the rover. This approach reduced motor use and allowed for faster excavation.

- Hopper: Inspired by dump truck mechanics, the hopper was placed beneath the trencher to catch and quickly deposit material. This minimized downtime between excavation and berm construction.

New This Year: Systems Engineering Subteam

For the first time, we introduced a dedicated subteam focused on documentation and systems engineering. This group tracked project progress, set technical requirements, and ensured that our workflow aligned with NASA and industry best practices. Their efforts gave the entire team a clearer roadmap and a stronger foundation for decision-making.

Lessons from Florida

Although this year’s rover was our most advanced yet, the competition brought unexpected challenges. Due to unforeseen issues, the rover wasn’t able to run in Florida. While disappointing, the experience taught us invaluable lessons about preparation, testing and resilience.

The systems we built and the systems we learned from will guide our next competition cycle. With stronger processes in place, we’re excited to keep creating, improving and dreaming big.

The moon may be far away, but with every rover, we get one step closer.

Mentors, Sponsors and Supporters

Behind every rover we work on is a community that makes it all possible. We are incredibly thankful for the sponsors, mentors and advisors who stand beside us throughout the year. They help shape our designs, challenge our thinking and equip us with the technical and professional skills we’ll carry into the engineering workforce.

2023-2024 Competition

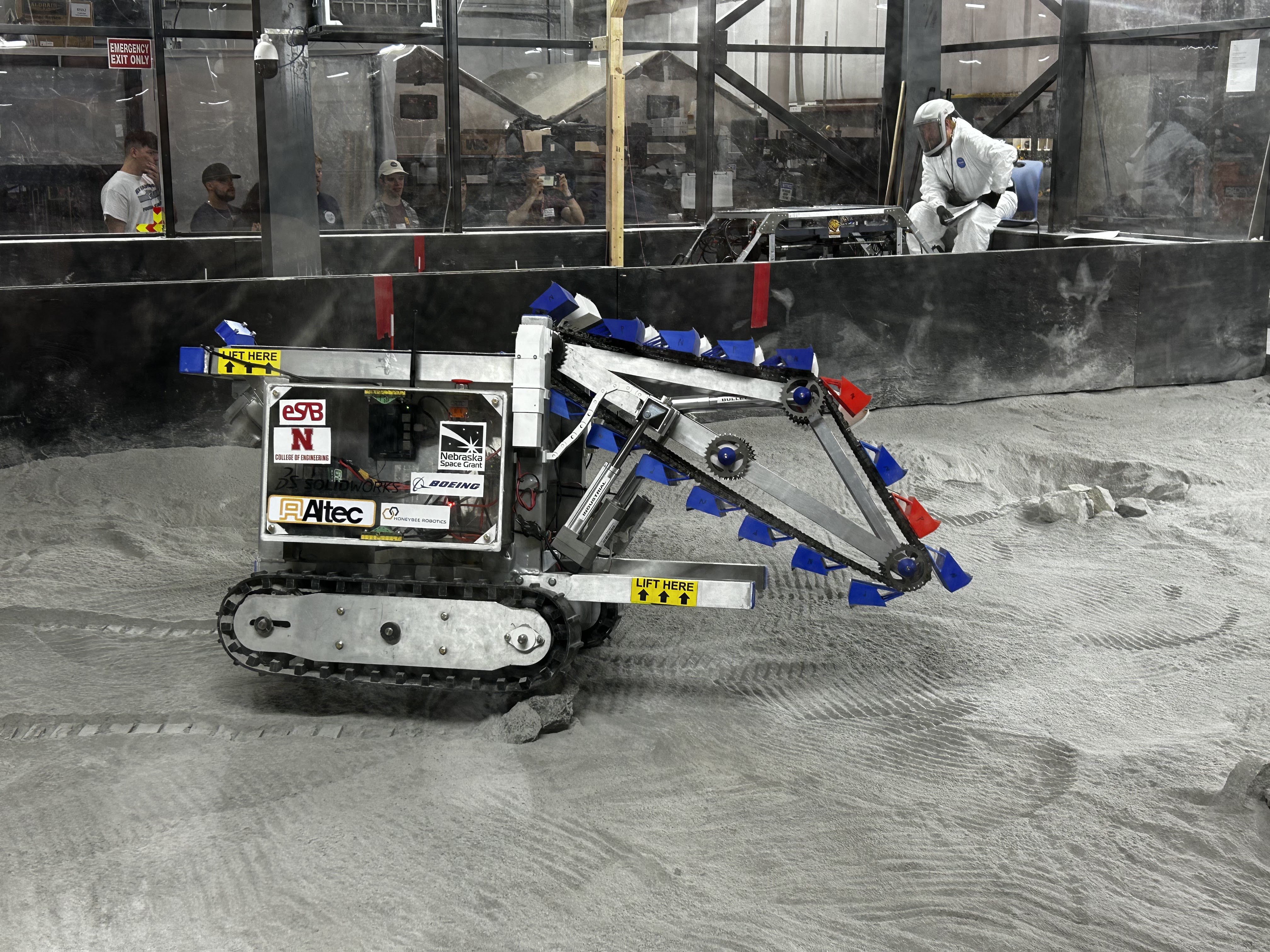

The 2023 - 2024 competition had a different objective than in prior year. Previously, the goal was to mine and deposit rocks remotely in a simulated lunar environment. Now, the robots are designed to dig a large quantity of lunar dirt and deposit it in a construction zone to build a berm. This new challenge forced our team to explore new design ideas.

The rover changed it design significantly from an auger to twin trenchers for speed and volume of excavated material. It also featured a large hopper system, and a tank track drivetrain design. This robot scored 6th place out of the 40+ teams at the qualifying competition hosted by University of Central Florida. Since our team placed in the top 10 qualifying teams we were able to compete at Kennedy Space Center. Unfortunately, tragedy struck when our communications system broke in an accident, resulting in no communication with the ground station and stopping our rover dead in its tracked. So, we scored 10th place.

2022-2023 Competition

The Lunabotics team preformed well at the 2023 RMC competition hosted by Alabama State University by placing 4th out of 30 teams, receiving the Leaps and Bounds Award for most improved team, placing 1st for the Public Outreach Award, receiving a perfect score for the Project Management Plan, and earning the Pheonix Award.

The robot featured an auger excavation system that scooped rock into the hopper. Once the tank track drive train carried the robot over the simulated lunar terrain, the hopper would deposit its material into the collection bin.